An ISO 9001:2015 registered, ITAR registered, Small Business

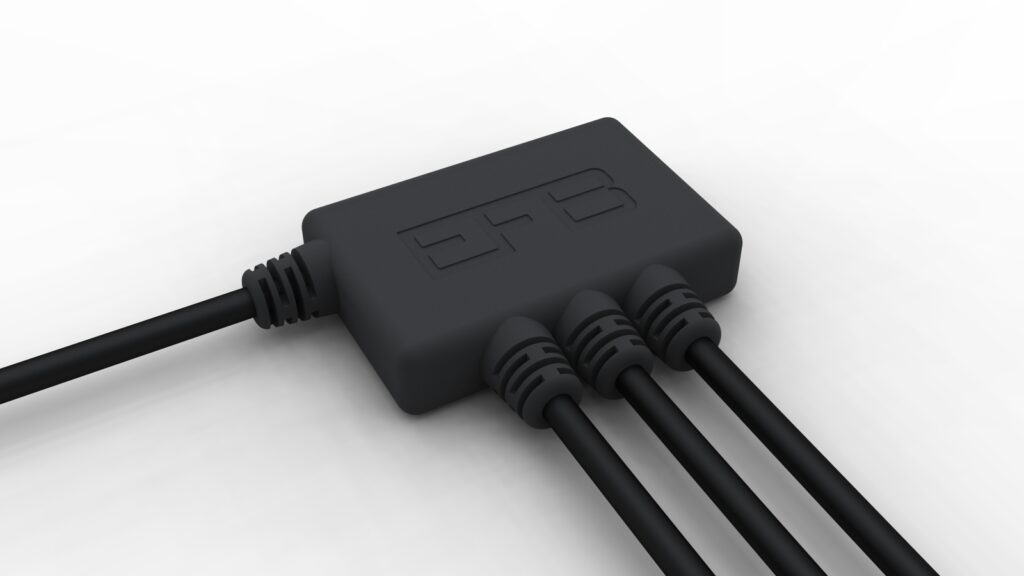

Prototype to high volume. Signal, power, and RF cables.

Power distribution units, radios, diagnostic equipment, power supplies, drone tethers.

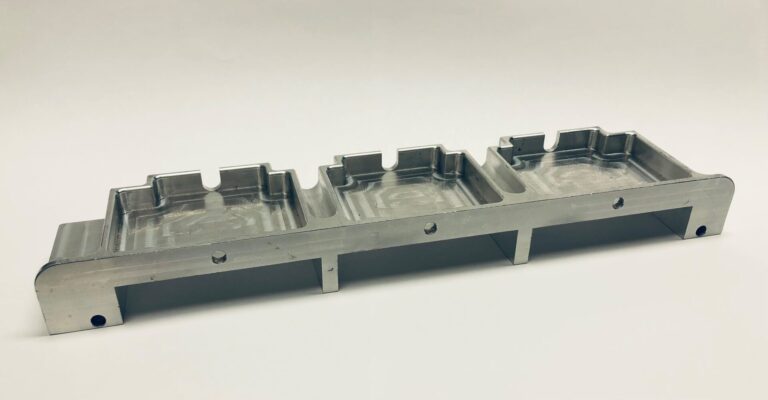

CNC, lathe, and electrical discharge machining.

Electrical, electronics, mechanical, industrial, and software development. From prototype development through product qualification services.

Continuity, Hi-Pot, Customized Testing, RF Testing

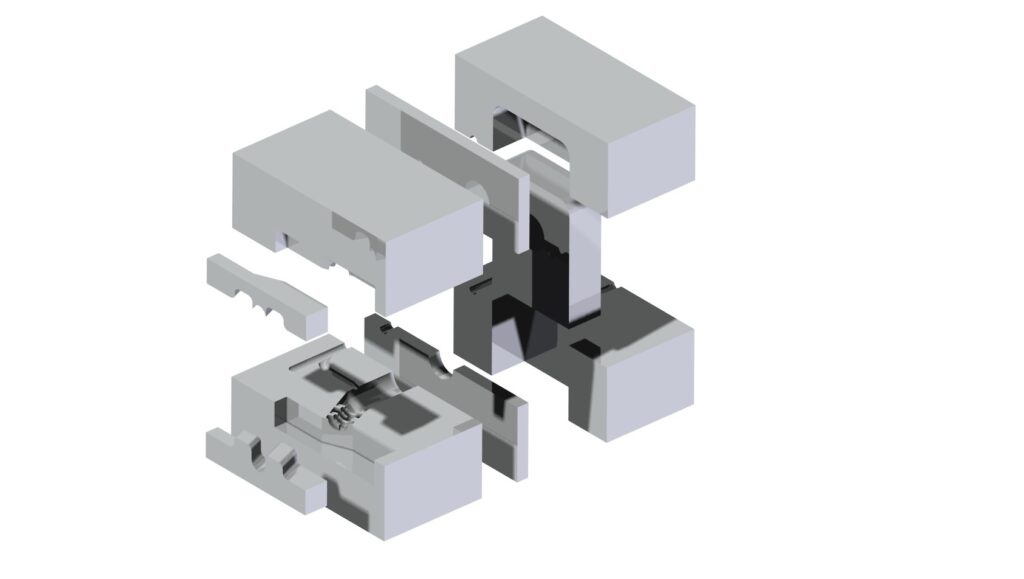

Turnkey injection molding solutions using vertical injection molding equipment.

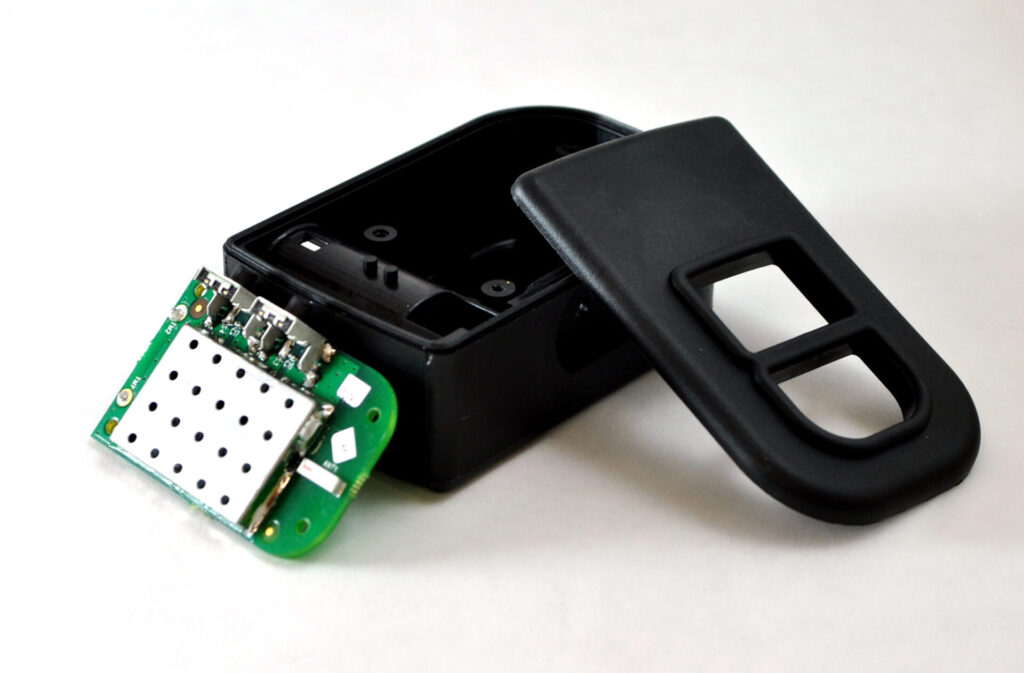

HT-128+

Case Study

See how the HT-128+ can enhance wire harness installation by quickly identifying wiring faults and mitigating expensive

downstream system test failures for an aerospace customer.

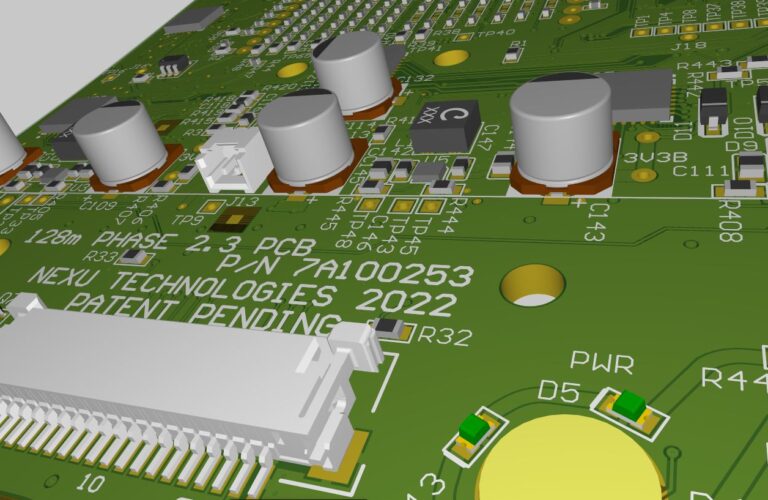

NEXU HT-128+

Wireless Harness Tester

Kinney Industries created a unique and robust testing solution, purpose built for installed wiring harnesses.

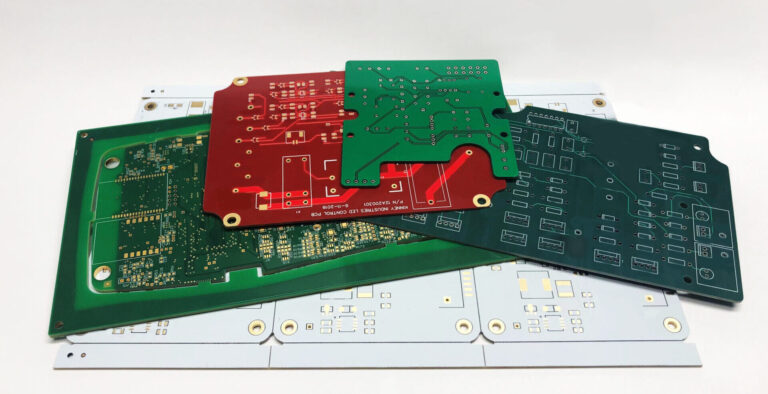

A few examples of

Our Work

In-House

Injection Molding

Kinney Industries can design, build, and deliver custom injection molded solutions for your project.

About

Kinney Industries Inc, has been serving the contract electronics manufacturing market since 1972. The company specializes in manufacturing a wide array of products including: cable and wire harness assemblies, electromechanical assemblies, machined components, and electronic assemblies.

Kinney Industries is an ISO 9001:2015 registered, ITAR registered, Small Business

Contact Us

Phone

Office: (256) 533-5580

info@kinneyindustries.com

Address

2514 Hall Ave. NW

Huntsville, AL 35805

Navigation

Contact Us

2514 Hall Ave. NW

Huntsville, AL 35805

(256) 533-5580

info@kinneyindustries.com